Knipex Crimping Pliers Self Adjusting for Wire Ferrules 180mm

$69.00

![]() Free & Fast Shipping

Free & Fast Shipping

![]() 30-Days Money-Back Guarantee

30-Days Money-Back Guarantee

![]() Lifetime Quality Warranty

Lifetime Quality Warranty

Knipex Crimping Pliers Self Adjusting for Wire Ferrules 180mm

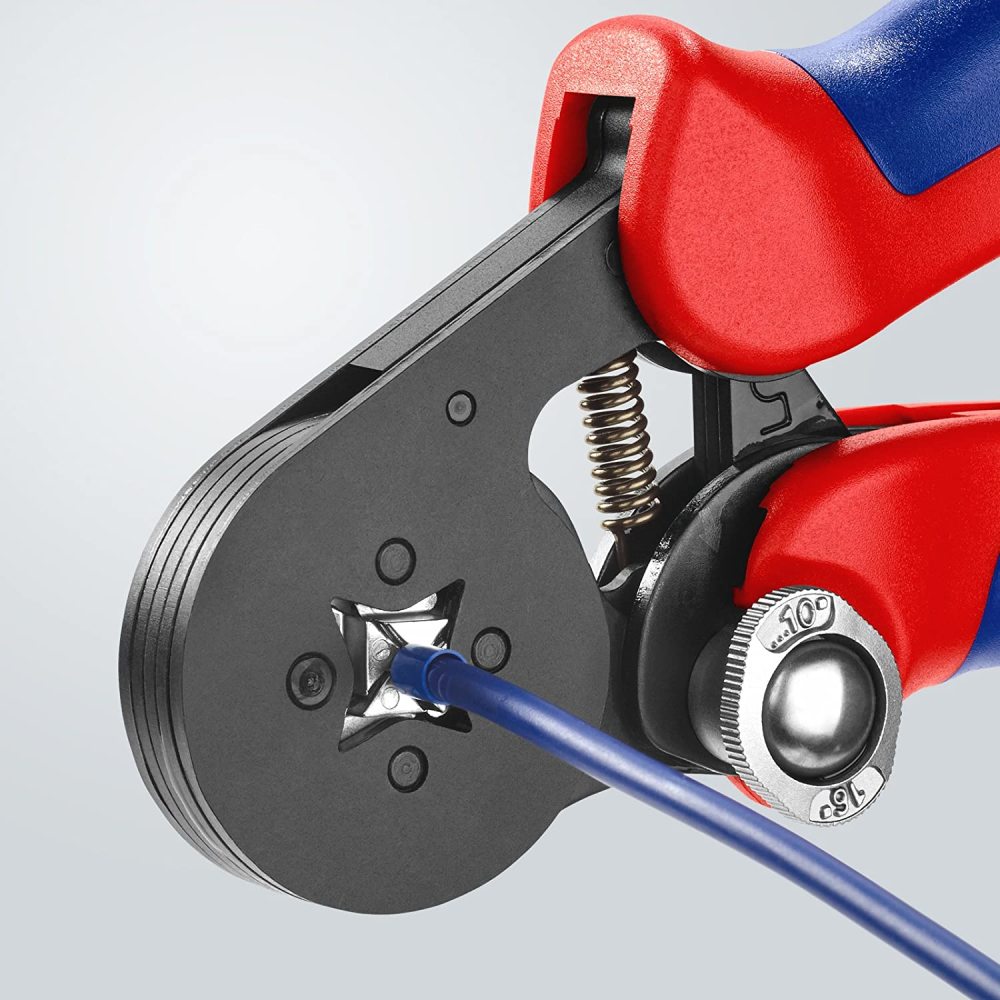

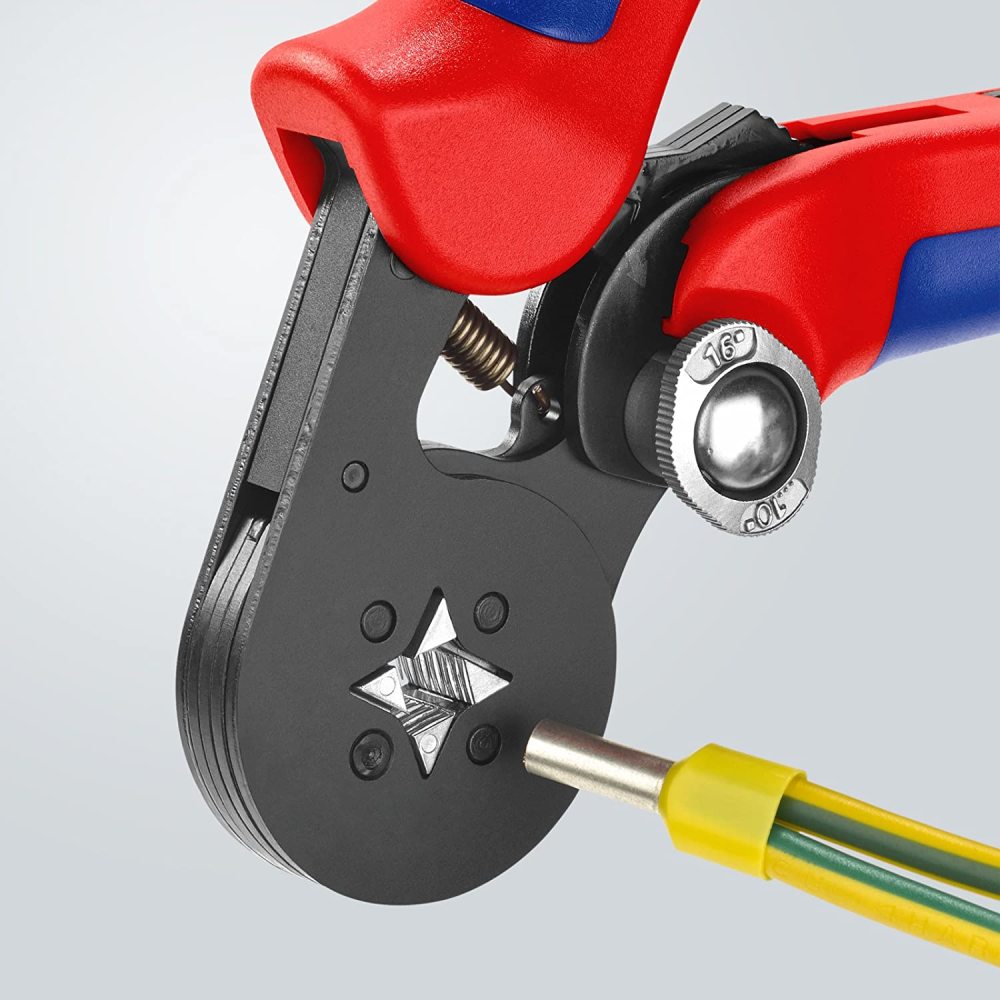

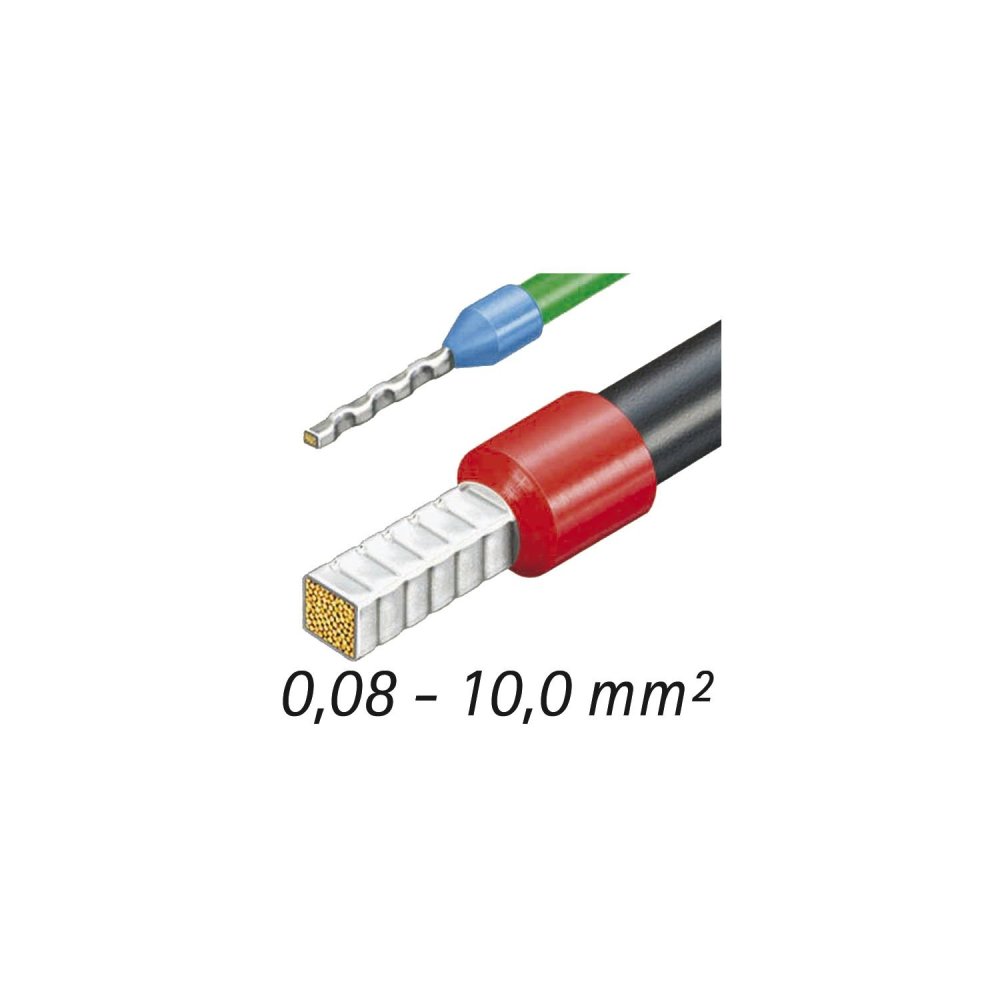

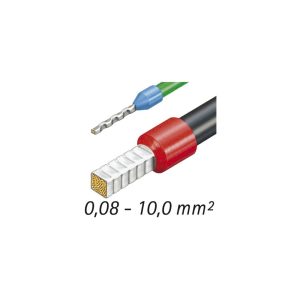

For reasons of design, it was a challenge to cover the wide capacity range of 0.08 to 10 mm2 + 16 mm2 using just one pair of crimping pliers. The result is technically sophisticated and easy to use. Knipex has applied for a patent for the design and operating principle of these crimping pliers. Accurate work is called for when crimping end sleeves (ferrules). Adjustment to the desired size of the end sleeves is automatic with the Knipex 97 53 04 crimping pliers. The user does not need to measure manual force when crimping because, thanks to the integral lock with release mechanism, the right amount of pressure automatically reaches the end sleeve. The pliers are optimally set (calibrated) in the factory. The transmission ratio of these crimping pliers has been well-designed and is therefore hand-friendly; it provides a comfortable grip width. A toggle lever effectively supports manual force. This enables conductors with large cross-sections to be assembled well even in the case of extensive installations – also with twin end sleeves (ferrules) up to 2 mm2 x 6 mm2 or 2 x AWG 8. The conductors are reliably connected to the end sleeves using a square profile – in all designated sizes. Knipex offers an extensive range of quality universal and special pliers for crimping. Those who use tools a lot and professionally every day expect a quality that permits simple and safe work and which lasts for many years of hard use. We manufacture our tools from quality materials, machine them with high precision on modern machinery and harden them with careful multiple stage heat treatment. Every pair of Knipex pliers represents more than 130 years of specialist know-how.

Narrow handle width and improved ergonomics

Square compression now additionally also for wire ferrules up to 16 mm2

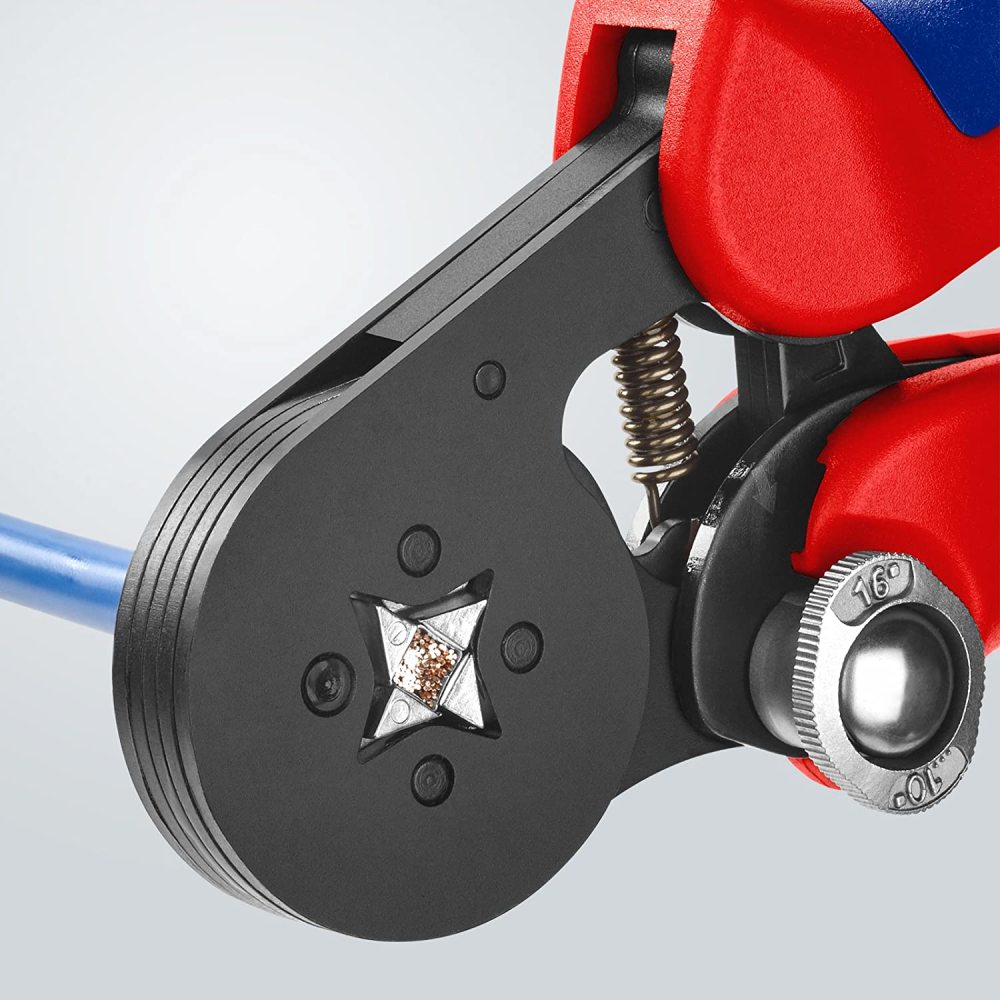

Square compression for ideal contact surfaces in the clamp connection

Suitable in particular for all twin wire ferrules up to 2 mm2 x 4 mm2 or 2 x AWG 12

For crimping wire ferrules according to DIN 46228 parts 1 + 4

Self-adjustment to the size of wire ferrules required

Repetitive, high crimping quality due to integral lock (self-releasing mechanism)

Tools have been set precisely (calibrated) in the factory

Optimum transmission of force thanks to toggle lever for fatigue-reduced operation

Related products

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools

Woodworking Hand Tools